How to Start a Pro Brewery

Business model, site selection and licensing

A clear business plan: The first step towards selecting a site and brewing system

Sauce Brewing Co in Marrickville, Sydney has a large, Spark 20 hL distributing brewery and enough space for a bar inside as well as a relaxed beer garden.

Selecting a business model

Braeside Brewing Co’s K5 is displayed next to the bar and can supply 30 kegs a week. They also have two bright tanks serving fresh beer directly to the bar.

. Business model 1. Brew on premise

Any newly licensed brewing company and most existing venues that sell 10 kegs a week can improve their profitability by brewing.

The small brewer’s excise remission scheme and Spark’s equipment finance assist with making this happen.

From 1 July 2021 the Excise remission scheme for manufacturers of alcoholic beverages (Remission scheme) provides eligible alcohol manufacturers with a full (100%) automatic remission of excise duty, up to a maximum of $350,000 per financial year, on alcoholic beverages they manufacture and enter into the Australian domestic market for home consumption - this is approximately 100 kegs a week!

Clear differentiation from competitors, with local keg distribution and growler take aways as additional revenue streams.

Requires a compact inexpensive brewing system that is easy to install and operate (SPARK K5 or K10).

Saves capital, space and time: the compact K5 and k10 design allows brewing, fermenting and serving from tanks built above fermenters: no need for messy, expensive and wasteful kegging, bottling or canning.

Your beer is presented in perfect, fresh condition, as it has not been exposed to light, heat or oxygen.

Drinkers of independent beer are a high growth, future relevant demographic.

Brewpubs are more popular with female clients than traditional pubs.

Fives times more profitable the the distribution brewing business model.

. Business model 2. Distribution brewing

Requires kegging and packaging for relatively low margin, high volume distribution, typically through third party wholesalers, distributors and retailers.

Relies on low unit cost of production via a large brewing system designed for multi batching each day up to double or quad batch fermenters.

Our smoothly welded tanks and ergonomic layout help make brewing and cleaning easier.

Selecting a business model and understanding the supply output you need is the first step.

Wandering Trout is a Craft Brewery in Mole Creek, on the scenic route to Cradle Mountain & World Heritage Wilderness.

Spark compact venue breweries are cost effective solutions to satisfy brew and serve on site business models.

Brewery Site Selection

The three tiers of brewing regulation in Australia

. Federal ATO manufacturers license to produce beer

This requires a fit and proper person check on personnel and defines a bonded area within the production facility.

Excise must be paid on product that leaves this area or is consumed on site. Calibrated measurement and detailed auditable records must track each step of production and packaging between malt in through to beer out.

https://www.ato.gov.au/Forms/Licence-to-manufacture-alcohol/

. State issued Liquor Licence to sell beer

Regulates hours of operation and maximum number of people permitted in the venue.

Victoria - https://www.vcglr.vic.gov.au/liquor/winery-or-brewery/apply-new-licence/apply-liquor-licence

Tasmania - https://www.treasury.tas.gov.au/liquor-and-gaming/liquor/applying-to-sell-liquor

QLD - https://ablis.business.gov.au/service/qld/commercial-other-artisan-producer-licence/44153

SA - https://www.sa.gov.au/topics/business-and-trade/liquor/apply/production-and-sales

WA - https://ablis.business.gov.au/service/wa/producers-licence/17122

. Local Council planning permission for use of the land for brewing

Considers potential impact on others in the area.

As with anything, there is both an easy way and a hard way to achieve the licences and permissions required. They are critical and should be approached with prior education, forethought and respect. Remember to allow time for your licenses to be processed.

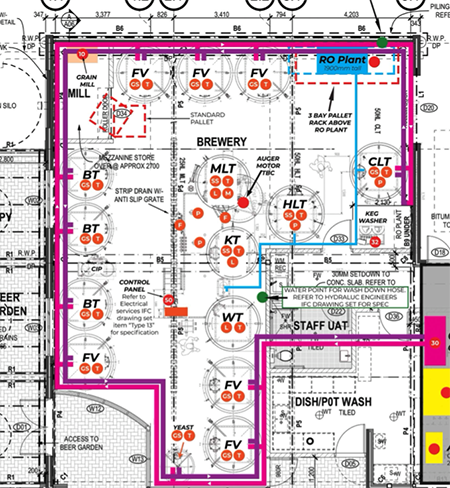

Spark assists our clients in council DA applications and decision support for licensing applications as well as produces professional layouts for submission.

Brewery design installation and startup

Brewhouse and fermentation cellar design should be related directly to your intended business model. Expansion is often more about forethought than money - by planning for success, you can make future expansion smooth and simple.

The amount of beer you can brew in a week is the same number of kegs as you have hL of cellar space.

E.g. if your fermentation cellar is 2 x 10hL (one hectolitre is 100L), your 20hL (2,000L) of cellar space will make 20 ale kegs per week.

. Brewing for serving on site

Optimise your brewery for space efficiency and good looks by dispensing your draft beer directly from serving tanks mounted above fermenters. This set up allows single batch brewing within a day. Instantaneous hot water systems and two stage (water & glycol) plate heat exchangers can avoid the need for hot and cold liquor tuns, saving capital and space.

The rule of thirds for the layout of a compact on site brewery: 1/3 of the space wet area for the brewery, 1/3 for circulation, 1/3 for serving.

. Brewing for distribution

Design for low energy costs and high output for every brewing hour.

3 or 4 vessel brewhouse configured with thermal stores for daily multi batching.

Thoughtful glycol system design to make it easy to add extra tanks as your sales increase.

Double or quad batch fermenters can be installed initially or added later.

Below is Froth Craft Brewery’s’ 25hL, utilising a much lower labour cost vs volume output, an ideal consideration for distribution brewing.

Froth Craft Brewery’s new Bunbury WA 25hl 3 vessel brewhouse with grist case.

Phil and Neil (L-R) from Burnley brewing in front of their newly delivered SPARK K500 2.0 brewhouse

Plan before you build

There are some important aspects of building fit out that are easy to include from the beginning, but expensive to have to retrofit at a later date such as wastewater treatment buffer tanks. This allows you to comply with any EPA requirements for cool, neutral pH effluent with low biological oxygen demand.

Digital controls are essential for brewing consistent, repeatable beers

Julian and Phil from Burra Brewing Co , at site discussing the build before the brewery's delivery. Spark Support our clients before during and long after the project installation.

The complete installed cost of a brewing system in operation is many times higher than the basic price of steel tanks - a control system that is well designed and locally constructed can backload a significant part of installation cost onto the equipment list (which can be financed), as all expensive electrical control hardware can be included upfront - this reduces the time and cost for installation.

Glycol and steam systems should be selected and designed to work well with your brewing system - reliability and maintainability are key once you are in operation

Critical Success Factors

Although it has been said that the crucial top three success factors in the brewing industry are selling beer, selling beer and selling beer, there are some additional things that could also be considered:

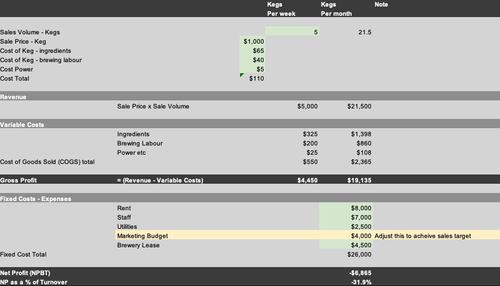

Planning

As the heart of a comprehensive business plan, get an accurate understanding of the costs of production for your chosen business model.

Staff, power, equipment finance costs (approximately $7,000 per month for a complete 10hL brewing system) and rent can be added to a basic $60 per keg for ingredients and 100% excise remission.

You could budget on a wholesale price of $300 per keg and retail (served on tap) of $1,100. Note the breakeven sales volume that will take you into profit and ensure that your business plan directly supports you achieving that as soon as possible.

See Sparkademy for our profitability calculator and how to use it.

Digital control

Give you all the details of your brew clearly at your fingertips and ensure that your superstar brewer can be busy designing your next beer, while the controls take care of making your beer correctly every time.

Spark supplies industry leading Melbourne designed and built digital controls for all of our breweries and distilleries.

Spark Customers

Beer Quality

Pivotal for the health of the industry as a whole, to justify consumer’s payment for and respect of our beer, a professional Quality Management based approach is needed for production. Much has been written on this and many training courses are available. A simple system need not require a prohibitively high laboratory equipment cost.

Pivotal for the health of the industry as a whole, to justify consumer’s payment for and respect of our beer, a professional Quality Management based approach is needed for production. Much has been written on this and many training courses are available. A simple system need not require a prohibitively high laboratory equipment cost.

Branding

As the embodiment of what you and your work stands for, clear, bold and consistent branding is important for standing out in an increasingly crowded marketplace.

Tap Sales

You’ll need to achieve 5 times the volume in distribution to make the same profit that you will via your own taps, so including a strong tap room in your plans gives you full margin revenue as well as a location to anchor your brand and organise consumer engagement events.

Quality reliable equipment

Real world success relies on your equipment being selected and installed in a way that ensures that it will operate reliably and can be maintained and repaired. The lowest cost option on day one is unlikely to actually end up being the lowest cost option after a year of brewing. No one with many years of experience in professional brewing, after multiple plant expansion projects, is choosing cheap equipment, for very good reason.

Steel comes in many different qualities of manufacture and finish. A well made tank will not only look good, more importantly it will be durable and easy to clean, making your brewer's work quicker and easier and safeguarding your beer from contamination from previous batches.

Our beautiful clean welds. As engineers, brewers and project managers we take equipment quality seriously and source high quality steel, fittings and digital meters.

Punters enjoy a froth at Ramblers Ale Works.